How does

the Detoxive

works?

Detoxive uses the most advanced artificial intelligence models and machine vision algorithms as well as image processing techniques to accurately detect aflatoxin.

The Detoxive device detects the permissible level of aflatoxin toxins in peanuts and corn without damaging the sample. The hyperspectral camera used in it detects the spectral characteristics of the sample with very high accuracy.

By analyzing the radiation spectrum caused by the toxin (fluorescence) and separating it from the radiation spectrum of the sample, the amount of aflatoxin toxin can be detected.

This product has two parts, software and hardware, which can be used to detect the dangerous amount of aflatoxin in corn and peanut samples.

Hardware

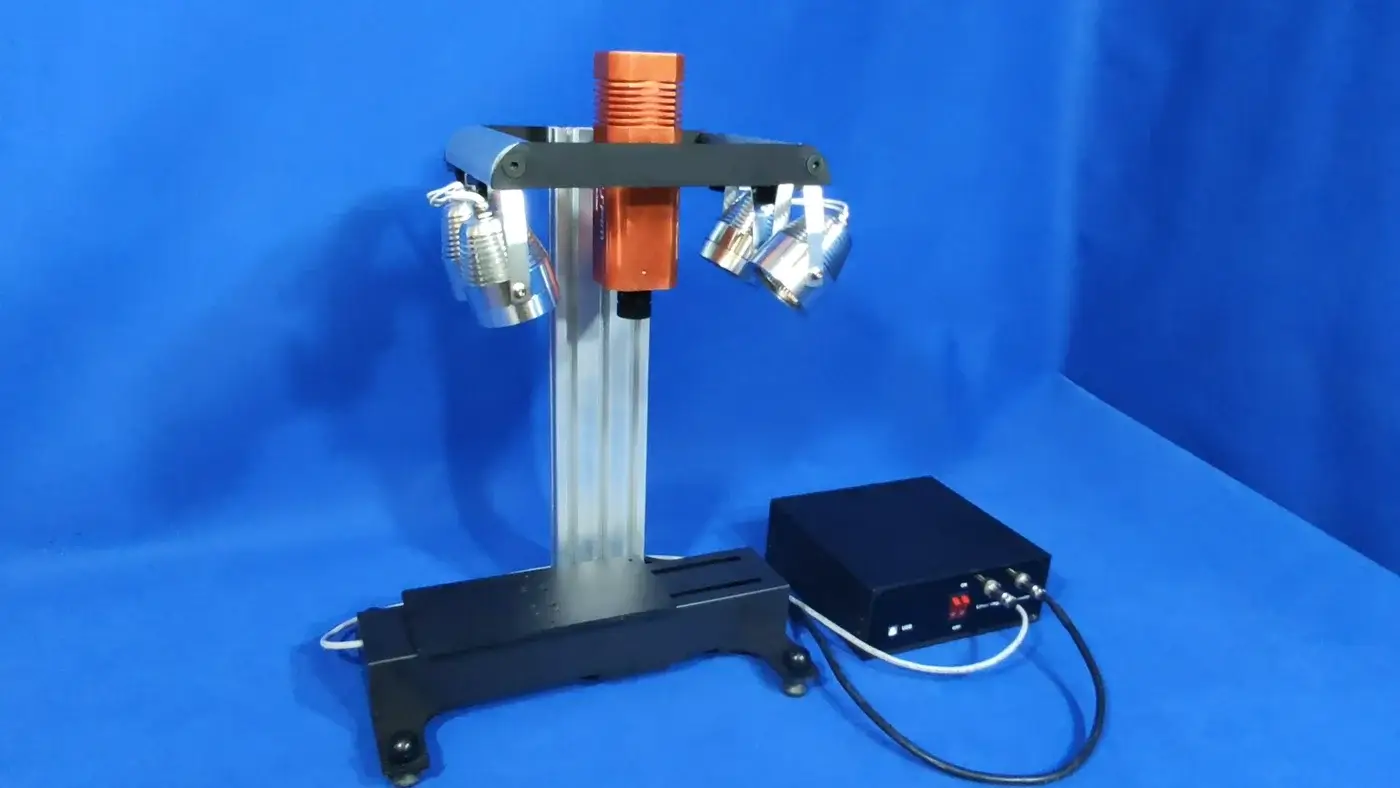

The hardware part of this product will consist of electric rails (with the ability to adjust the movement speed), a UV lamp, a hyperspectral camera, and an optical filter. Due to aflatoxin's 365 nm fluorescence, a UV lamp at this wavelength will provide evidence of aflatoxin's presence. By irradiating the sample with UV light, the aflatoxin toxin will emit fluorescence and be distinguished from the rest of the sample.

At this stage, the hyperspectral camera will be responsible for capturing images. The reason for using this camera is that it will detect a wavelength range of 400-850 nm for each pixel of the image with an accuracy of 2 nm, which allows us to receive changes in radiation peaks due to the presence of toxins. By measuring the fluorescence peaks of the fluorescence camera, the dose of toxin in it will be measured. If this amount is more than allowed, the software will display it in a different color.

Advantages of using a hyperspectral camera:

Accurate and rapid detection

Detection without damaging the sample

Cost-effective (considering the volume measured in a short time)

It can be applied in inline procedures

Software

The software is designed based on Windows, which is user-friendly. The speed and accuracy of the analysis can be defined. One of its unique features is identifying samples with a dose higher than the allowable amount of aflatoxin toxin. In addition, it will be able to display the weight percentage of infected and healthy samples separately.

First, the software will allow you to enter the type of material under analysis to make the default settings based on it.

In the second step, by specifying the line speed and the weight of the material, the software will display the measurement accuracy and the estimated time to perform the whole process. The user will press the start button.

The software will display the camera data, and the processing will be performed live by starting the process. If needed, the user can record images or videos. The contaminated sample will be distinguished from the healthy sample using a different color at this step. If the user wants to stop the process at this step, the user can cancel by the cancel button.

At the end of the process, the software will show the approximate total weight and weight percentage of healthy and infected samples separately, and the user will be able to save the data.